WPC Decking Compuesto Fabricante Composite Decking Tile ISO EU Standard

Description

Wood-plastic composites (WPCs) are composite materials composed of wood elements combined with plastic fibers. WPC can be made entirely from recycled materials and plastic powder obtained from wood product manufacturing facilities. Also known as composite wood, WPC is widely used to build outdoor deck floors, prefab homes, park benches, door frames, and indoor and outdoor furniture.

Manufacture of Wood Plastic Composites (WPC)

Wood-plastic composites are made by thoroughly mixing ground wood particles with heated thermoplastic resin. Finally, the entire mixture is extruded into the desired shape. Commonly used thermoplastic resins are polystyrene (PS), polylactic acid (PLA) and polypropylene (PP).

Mixing and extrusion processes vary by manufacturing facility. WPC contains organic raw materials and needs to be processed at lower temperatures than traditional plastic composites to facilitate extrusion and injection molding. The ratio of wood to plastic in the composite determines the melt flow index (MFI) of WPC. Larger amounts of wood result in lower MFI.

Characteristics of Wood Plastic Composites (WPC)

WPC is made up of a combination of substances prepared in a paste-like texture. Therefore, they are molded into any desired shape and size.

WPC can be dyed or tinted to match the desired design specifications.

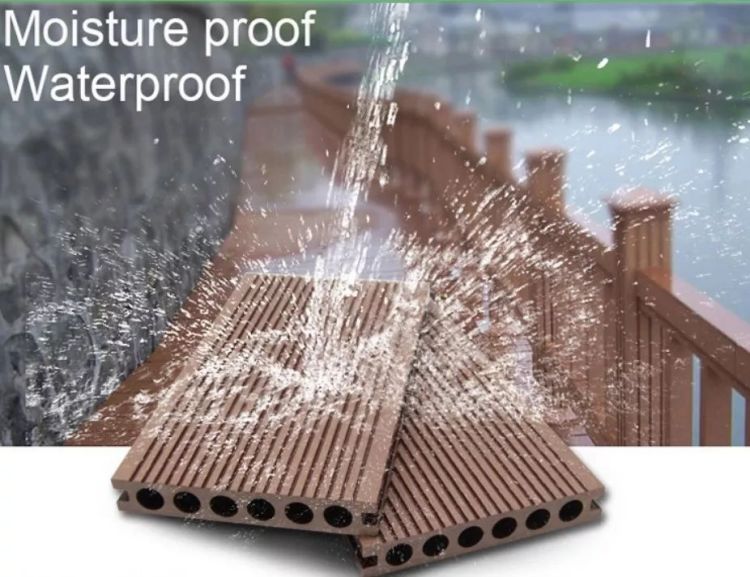

Compared to regular wood, WPC is both aesthetically and overall durable because this composite material resists moisture and corrosion.

WPC is more heat resistant than typical wood.

Drilling, planning and sanding work on WPC is similar to normal woodworking.

Additives added to the WPC manufacturing process give the product better dimensional stability than regular wood.

Advantages of Wood Plastic Composites (WPC)

WPC material is termite resistant and waterproof.

WPC boards provide a good surface finish without the need for painting, staining and oiling.

WPC material requires less maintenance and can withstand extreme weather conditions.

Compared to regular wood, WPC material is more durable and lasts longer.

WPC floors are non-slip.

WPC materials are available in different colors and painted with different textures.

WPC can be thermoformed into any curved or curved shape.

The material is UV resistant, so it won't fade when used outdoors.

WPC is made from recycled wood and plastic materials. Therefore, it is a sustainable and environmentally friendly material.

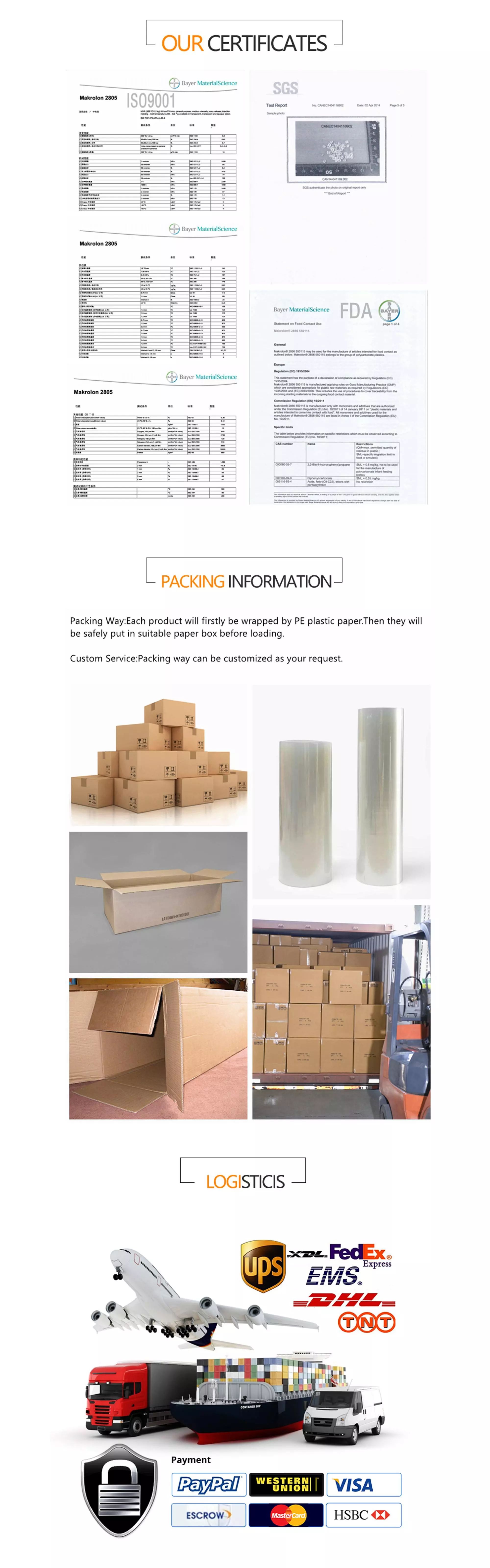

Product Name Outdoor Decking Model Number TB-02 Specification 140mm*25mm Material PVC foam+ASA Warranty More than 5 years Certificates CE,ISO

JIANGSU TUBO NEW MATERIAL CO.,LTD our factory which is a high technology and comprehensive company specializing in integrated design, research and development, manufacture, sales and service.Headquarter Located in Jiading District, Shanghai. We are a professional manufacture new materials like PLA ,PTFE, EVA, PVC ,Acrylic And Wood-Plastic Composites and other more than ten series of materials of the new material company.

Based on the "quality" and "service",TUBO Materials has been widely used by customers all over the world. between team, within the team, we are sincere, cooperative attitude and determination to build our destiny and career community. Whether it is in management or in products, it is the driving force to maintain the superiority of our team.