HDPE Paper Tyvek dyed 1056D non-woven fabric environmentally friendly waterproof tear-resistant handbag light box fabric

Product description

Summary of materials

TUBO paper is a high-density polyethylene material made by a special process .

Because of its unidirectional air permeability, it is also called "breathing paper".

Tyvek was invented in the 1950s and commercialized in the 1960s. Tyvek is a high-density polyethylene made of high-density polyethylene that is processed into continuous filaments by thermal melting and then thermally bonded by using flash evaporation technology. This unique process technology allows Tyvek to combine paper, film and woven fabrics. All in one, waterproof, breathable, lightweight, strong, tear-resistant, puncture-resistant, high reflectivity, diffuse reflectivity, UV-resistant, unique texture and touch, environmentally friendly, recyclable, and compatible with various printing technologies And most of the digital printing technology, suitable for a variety of processing techniques. Tyvek has a wide range of uses, and is often used as waterproof and breathable materials for exterior walls and roofs, sterilization packaging materials for medical equipment, and chemical protective clothing in the field of industrial personal protection. In recent years, Tyvek has also been widely used in various civil design and creative products, such as fashion household items, fashion, art, cultural and creative products, environmental protection and creative packaging, etc. Tyvek is pure white and comes in two different constructions: a hard structural material like paper and a soft structural material like cloth.

Performance

Good protection. Excellent resistance to chemical substances: chemically inert to most acids, alkalis, and salts, and has a good liquid barrier protection function. Waterproof and breathable. Porous material with good air permeability. Due to the fine fibers, liquid water, oil, etc. cannot easily penetrate; while gas and water vapor can pass through, it has excellent waterproof and breathable performance. Good anti-solid particle penetration function. The special physical structure can completely block fine mites and dust and prevent them from penetrating. Excellent antibacterial effect. It can be applied to the packaging of sterile medical products. Low fuzz. Durable and lint-free. High strength and excellent dimensional stability. Easy to process, since it does not absorb water, its dry and wet strength does not change. Determined by the nature of the material itself, the size basically does not change with humidity. At constant temperature, in the range of relative humidity 0~100%, it can maintain excellent dimensional stability. It can still maintain toughness and flexibility at -73 degrees; it begins to shrink at 118 degrees; it begins to melt at 135 degrees. Therefore, the heating temperature should not exceed 79 degrees to avoid deformation. It is not recommended to iron the finished home textile products. Excellent flexibility. Folding-resistant, allowing more than 20,000 times of repeated folding, durable. Health and Environmental Protection. Will not cause environmental pollution. It is an environmentally friendly material. After complete combustion, only carbon dioxide and water vapor are produced. light weight. Compared with ordinary cloth, it is only a fraction of its weight. Its weight per square meter is only half that of paper of the same thickness. High-tech protective material. Tyvek ADM is a special fabric made by TUBO's original flash method, which can only be produced by TUBO in the world. It combines the advantages of paper, film, and cloth. It is strong and durable, waterproof and breathable, soft and strong, and has stable and balanced physical properties.

Material properties

TUBO paper has the advantages of paper, film and cloth, but also has its own characteristics.

1. Waterproof, breathable, light weight

Due to the fine fibers, liquid water, oil, etc. cannot easily penetrate, but gas and water vapor can pass through, with excellent waterproof and breathable performance.

2. Strong, tear-resistant and puncture-resistant

The special fabric made by the original flash method,

It combines the advantages of paper, film, and cloth. It is strong and durable, soft and strong, and has stable and balanced physical properties.

3. Anti-bacterial, anti-ultraviolet

Good anti-penetration function of solid particles, special physical structure, can completely block fine mites and dust, prevent their penetration, excellent effect of blocking bacteria.

4. Resistant to 100°C high temperature

At constant temperature, in the range of relative humidity 0~100%, it can maintain excellent dimensional stability.

It can still maintain toughness and flexibility at -73 degrees, it starts to shrink at 118 degrees, and it starts to melt at 135 degrees. It is not recommended to iron its home textile products.

5. 100% recycling

Durable and green.

Manufacturing process

Using flash evaporation technology, the polymer is processed into continuous filaments after hot melting

It is then thermally bonded, and the unique process makes TUBO paper have good fire resistance. With the nomex tape itself, which is an insulator, it can well meet the design's fire protection requirements.

The unique manufacturing process makes TUBO paper tough and durable, has strong tear resistance, and can strongly resist natural and artificial stretching. As the facade of a building, there is no need to worry about cracking caused by stretching .

TUBO paper can be applied to many products, such as desiccant packaging, medical packaging, protective clothing, walls, laminated roof insulation, down lining, envelopes, packaging materials, automotive sheathing, etc.

Material properties:

●Waterproof

● One-way ventilation

●High strength, tear resistance, from completely wet to completely dry, the stretching and shrinking ratio of the paper surface is not as good as

0.01%.

●Aging resistance

●Light texture

●Printable

●High light resistance

●Acid and alkali chemical corrosion resistance, not afraid of most strong acids, strong alkalis and salts

●Environmentally friendly products After complete combustion, only water vapor and carbon dioxide remain, which does not affect the environment at all

● -73℃ is always soft

In terms of environmental protection, Tyvek is mainly made of high-density polyethylene (HDPE) polymers without plasticizers. The production process does not add restricted chemical substances listed in EU directives such as RoHS, or "substances of high concern" listed in REACH. "(referred to as SVHC); NOMEX complies with the requirements of ROHS regulations.

Element

Tyvek: high-density polyethylene (HDPE); free of binders, fillers, brighteners (such as titanium dioxide), etc., pure ingredients.

Application case

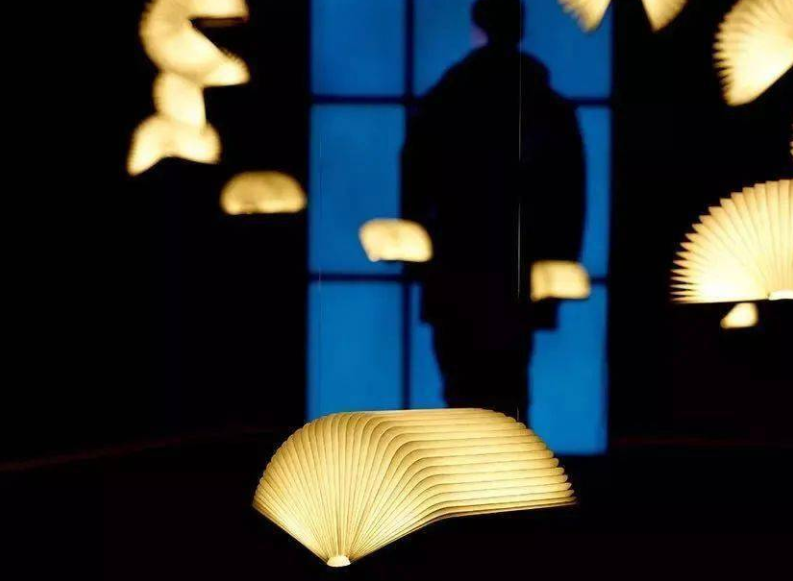

1. The main exhibition hall on the first floor of Shenzhen World Culture and Art Center

2. Apple flagship store in Japan

3. Applied to home furnishing, art, clothing

△Lamps

△Installation art

△Furniture

△Furniture and daily necessities