8mm PVC Foam Board and 12mm Plastic Board PVC Furniture Foam Board

PVC Foam Board and 12mm Plastic Board PVC Furniture Foam Board

Description

PVC foam board, also known as sheaf board and PVC foam board, its chemical composition is POLYvinyl chloride.

Product features

2. The same processing as wood, and the processing performance is far better than wood

3. It is an ideal substitute for wood, aluminum and composite board

4. The surface of the board is very smooth, high hardness, not easy to scratch, often used for making cabinets, furniture and so on.

Product Usage

Widely used in passenger cars, train car ceilings, box core layers, interior decorative panels, building exterior wall panels, interior decorative panels, office, residential, public building compartments, commercial decorative frames, clean room panels , ceiling panels, screen printing, computer lettering, advertising signs, exhibition panels, photo album panels for signs and other industries and chemical anti-corrosion engineering, thermoforming parts, cold storage panels, special cold insulation engineering, environmental protection molds, sports equipment, aquaculture materials , seashore moisture-proof facilities, water-resistant materials, art materials and various lightweight clapboards instead of glass ceilings.

Pvc Foam Board Information Material pvc material Density 0.35-1.0g/cm3 Thickness 1-35mm Color white.red.yellow.blue.green.black.etc. MOQ 3 tons Size 1220*2440mm,915*1830mm,1560*3050mm,2050*3050mm Finished glossy & matt Quality Control Triple Inspection System:

1.selection raw material 2.monitoring the whole process 3.checking pc by pc .Package 1 plastics bags 2 cartons 3 pallets 4 kraft paper Application advertisement &furniture &printing &construction .etc Delivery Date after received deposit about 15-20 days Payment TT , L/C , D/P , Western Union Sample Free samples are available

| Pvc Foam Board Physical Properties | ||

| Testing Item | Unit | Testing Result |

| Density | g/cm3 | 0.35-1.0 |

| Tensile Strength | Mpa | 12-20 |

| Bending Intensity | Mpa | 12-18 |

| Bending elasticity Modulus | Mpa | 800-900 |

| Impcting Intensity | KJ/m2 | 8-15 |

| Breakage Elongation | % | 15-20 |

| Shore hardness D. | D | 45-50 |

| Water Absorption | % | ≤1.5 |

| Vicar Softening Point | ºC | 73-76 |

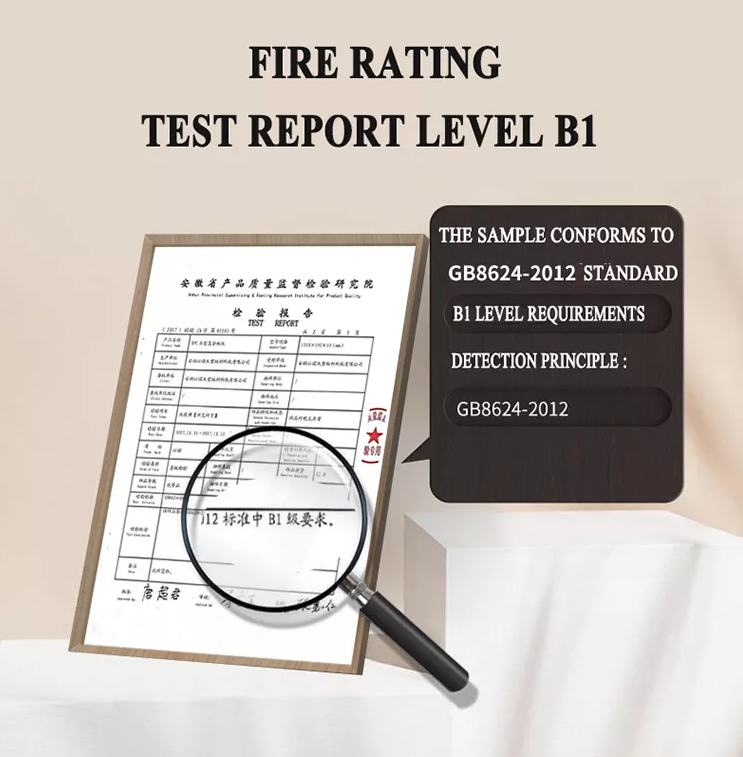

| Fire Resistance | Self-Extinguishing Less than 5 seconds | |

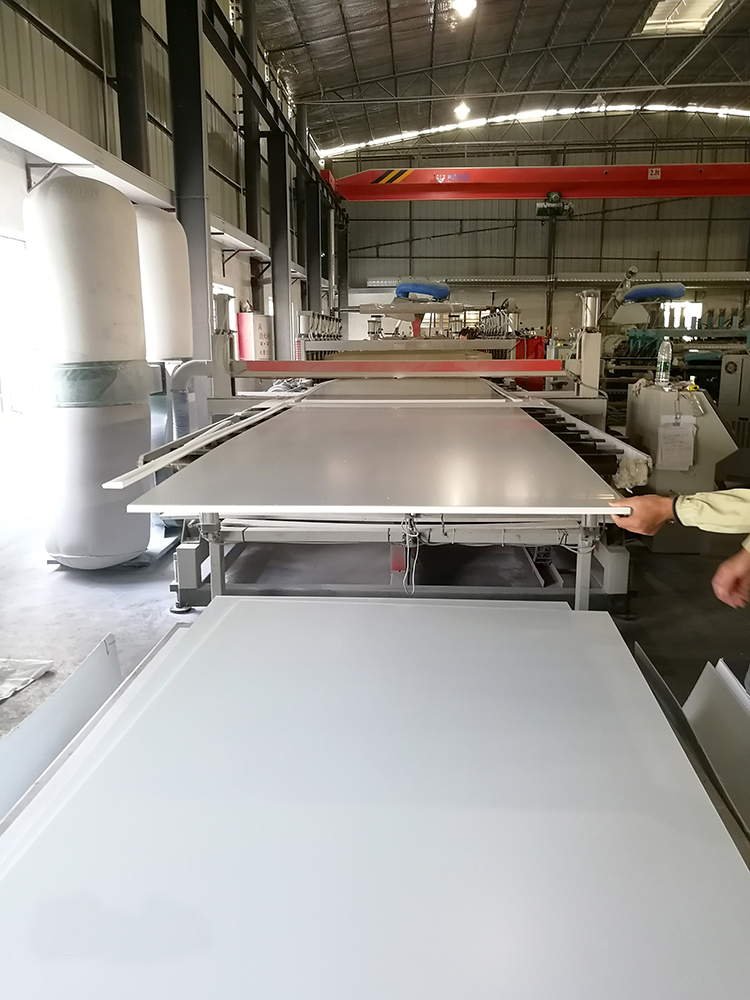

Team

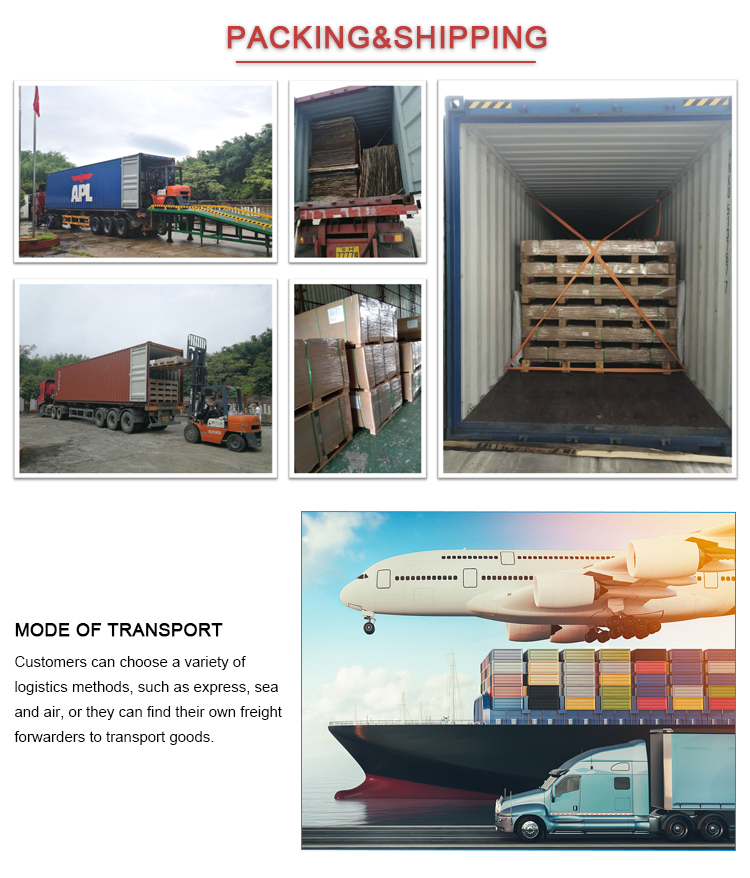

Shipping