PLA Sharp Biodegradable Compostable Jumbo Bubble Tea Drinking Straw 12mm

Description

PLA material - emulsified from corn or starch, it is a natural raw material. The temperature tolerance is -10°C to 80°C, which is close to plastic straws, and has the same physical properties as traditional plastic straws, so there is no discomfort in daily use. At the same time, after being used and discarded, it can be decomposed into water and carbon dioxide under composting conditions for 45 days, which will not cause ecological pollution, and is a very good environmental protection straw.

With the continuous development of the social economy and the continuous growth of the global population, the earth's resources have been seriously exploited, and environmental and energy problems such as global warming and the depletion of petroleum resources have become more and more serious. The environmental pollution caused by the production, consumption, disposal and other processes has become increasingly prominent, and people have realized the importance of protecting the environment. Therefore, in recent years, non-petroleum-based degradable materials have attracted more and more attention. Among the many biodegradable materials, polylactic acid, as a new type of environment-friendly polymer material, has gradually attracted people's attention.

Polylactic acid (PLA), also known as polylactide, is a polyester polymerized from lactic acid. Polylactic acid has excellent biodegradability, compatibility and absorbability. Polylactic acid is a non-toxic and non-irritating synthetic polymer material. Its raw material is lactic acid, mainly from the fermentation of starch (such as corn, rice), etc. It can also be obtained from cellulose, kitchen waste or fish waste as raw materials. PLA has a wide range of raw material sources, and the products made from it can be directly composted or incinerated after use, which can ultimately completely reduce CO2 and H2O to meet the requirements of sustainable development. The good transparency and certain toughness, biocompatibility and heat resistance of PLA are the main reasons for its wide application. In addition, PLA is thermoplastic and can be used in many fields. Products prepared with it, such as packaging materials, fibers, etc., are mainly used in disposable products such as disposable tableware and packaging materials, car doors, floor mats and car seats, etc. Apparel, electrical appliances and medical and health care (orthopaedic internal fixation materials and non-removal surgical sutures, etc.) and other fields. Compared with traditional petrochemical products, the energy consumption of polylactic acid production process is only 20%~50% of that of petrochemical products, and the carbon dioxide produced is only 50% of that of petrochemical products. Therefore, the development of polylactic acid degradable materials is very necessary to alleviate global environmental and energy problems.

Characteristic

1. Biodegradability

Compared with traditional plastics, polylactic acid can be degraded into CO2 and H2O by microorganisms, light, etc. Its degradation products are non-toxic and harmless, and will not pollute the environment. The monomer for producing polylactic acid is lactic acid, which in turn can be produced by fermentation of crops or agricultural by-products such as wheat, rice and sugar beets. Therefore, the raw materials for the production of polylactic acid are reproducible. As a new biodegradable material, polylactic acid has a wide range of applications.

2. Biocompatibility and absorbability

Polylactic acid can undergo acid or enzymatic hydrolysis to generate lactic acid in the human body. As a metabolite of cells, lactate can be further metabolized by enzymes in the body to generate CO2 and H2O. Therefore, polylactic acid is non-toxic and harmless to the human body, and has good biocompatibility and bioabsorbability. PLA is certified by the U.S. Food and Drug Administration as a biomaterial for implantation in the human body.

3. Physical processability

As a thermoplastic polymer material, polylactic acid has good plasticity and physical processing properties, high melting point and crystallinity, good elasticity and flexibility, and excellent thermoformability. Like polymer materials such as polypropylene (PP), polystyrene (PS) and polyphenylene ether resin (PPO), polylactic acid materials can be processed by extrusion, stretching and injection blow molding.

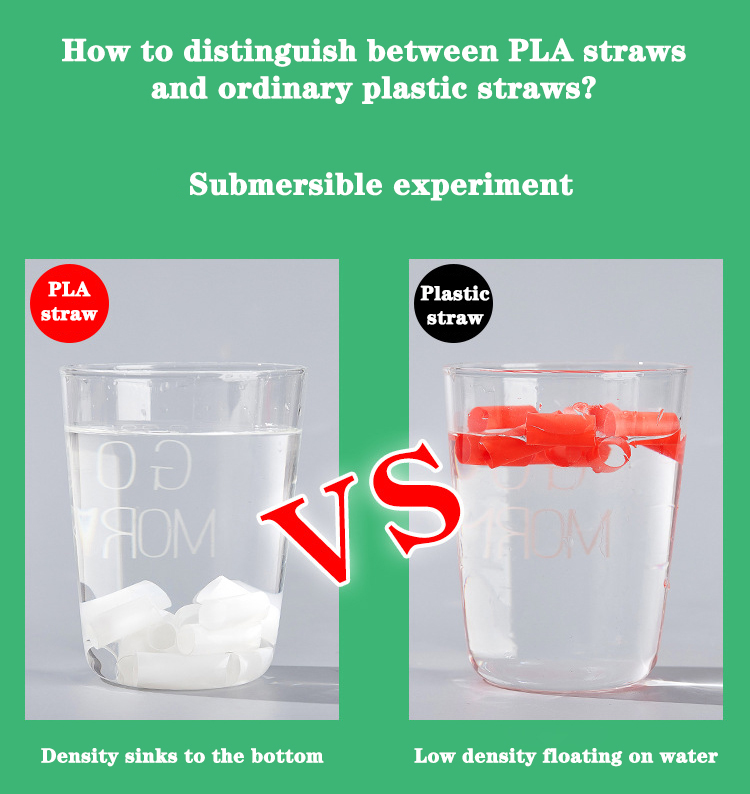

PLA straws

PLA degradable straws are made of a new type of bio-based and renewable biodegradable material called PLA, also known as polylactic acid. It is made from starch raw materials proposed by renewable plant resources (such as corn, cassava, etc.), and is degradable. Ordinary plastic straws are not degradable.

PLA polylactic acid straws use starch as the main raw material. Because starch is a biodegradable natural polymer, it can be decomposed into water and carbon dioxide in 45 days under composting conditions after being discarded, which does not pollute the environment; while ordinary plastic straws are used and discarded. It will not degrade automatically, and it will pollute the environment to a certain extent.

The appearance and performance of PLA degradable straws are close to the traditional straw products made of polypropylene. The product has good gloss and transparency, and has the advantages of safety, hygiene, environmental protection, and biodegradability. The shelf life can reach 12 months.

JIANGSU TUBO NEW MATERIAL CO.,LTD our factory which is a high technology and comprehensive company specializing in integrated design, research and development, manufacture, sales and service.Headquarter Located in Jiading District, Shanghai. We are a professional manufacture new materials like PLA ,PTFE, EVA, PVC ,Acrylic And Wood-Plastic Composites and other more than ten series of materials of the new material company.

Based on the "quality" and "service",TUBO Materials has been widely used by customers all over the world. between team, within the team, we are sincere, cooperative attitude and determination to build our destiny and career community. Whether it is in management or in products, it is the driving force to maintain the superiority of our team.