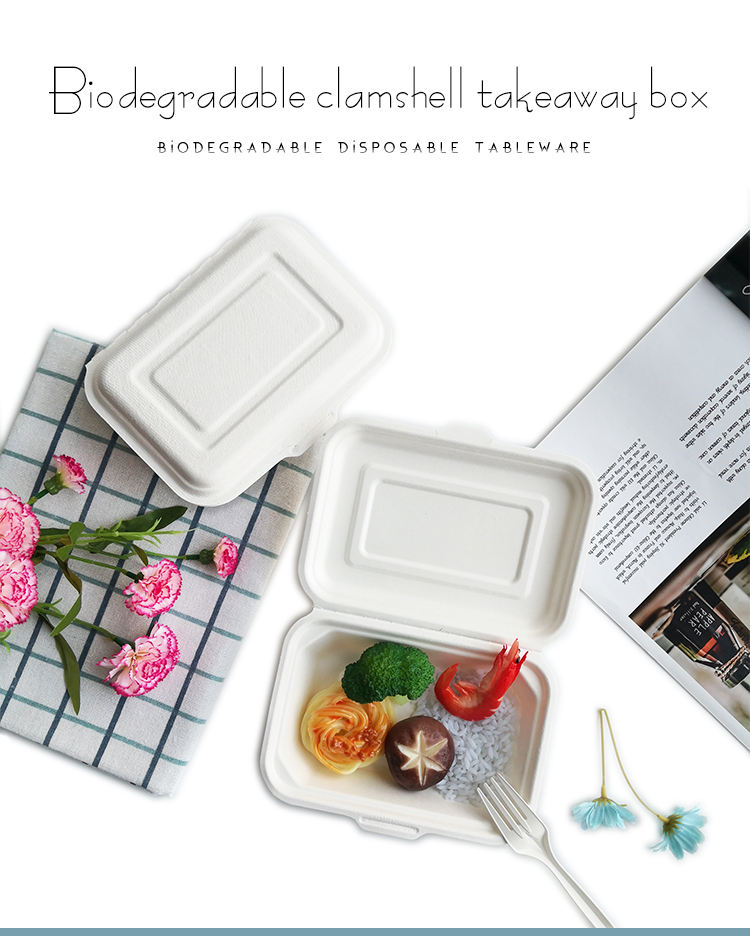

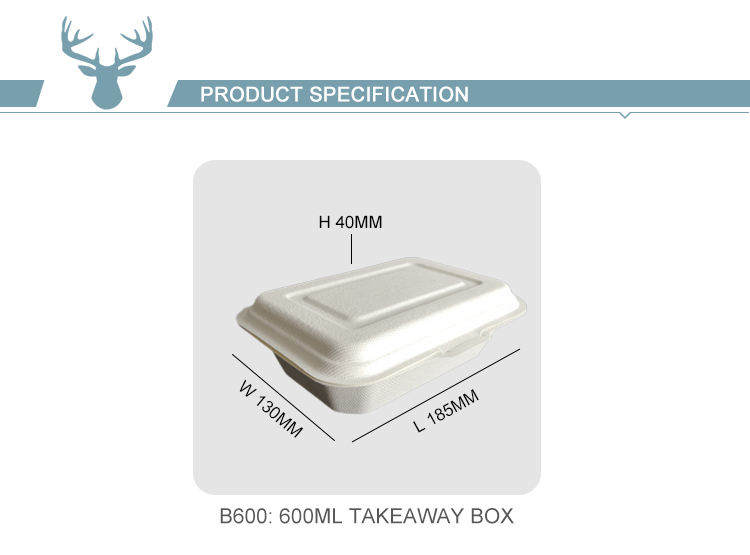

Biodegradable Food Containers Disposable Takeaway Pla Lunch Box

Description

Polylactic acid is a polymer obtained by polymerizing lactic acid as the main raw material, and it is a new type of biodegradable material. Polylactic acid, also known as polylactide, belongs to the polyester family.

It is an inevitable trend for polylactic acid fully degradable tableware equipment to replace disposable plastics 1. 100% biodegradable: pla is made of starch raw materials proposed by renewable plant resources (such as corn, cassava, etc.), tableware wholesale is a kind of New bio-based and renewable biodegradable materials, starch raw materials are saccharified to obtain glucose, and then fermented from glucose and certain strains to produce high-purity lactic acid, and then chemical synthesis methods are used to synthesize a certain molecular weight. It has good biodegradability and can be completely degraded by microorganisms in nature after use. 2. Pla comes from nature and belongs to nature: at present, the most common disposable lunch boxes such as take-out packaging boxes, restaurant packaging boxes, and supermarket food boxes are mostly petroleum-based materials, and the production process will contain more The additives may cause cancer in the human body. Waste lunch boxes can only be disposed of by burial or incineration. Burial will harm soil and water sources, and the gas generated by incineration will cause a large amount of greenhouse gases to be discharged into the air. Bio-based materials from renewable resources such as corn and sugarcane can be 100% decomposed into carbon dioxide and water in nature, solving the problem of white pollution from the root and achieving sustainable development. 3. Urgent environmental status and policies: According to incomplete statistics, the world’s carbon dioxide emissions will rise to 60°C in 2030 according to news reports. This is a terrible data. The World Environmental Protection Organization is also vigorously urging its members to Pay attention to environmental protection. In recent years, my country's "environmental protection action" is really moving towards the goal of "green mountains and clear waters", which will make the polylactic acid market reach 300,000-500,000 tons in 2020. The ban on plastics has been implemented in Hainan Province. I believe that in the near future will be widely promoted. It is an inevitable trend for polylactic acid fully degradable tableware equipment to replace single-use plastics To the inevitability of the development of polylactic acid tableware, the reform of living standards will inevitably bring about the reform of products, and the reform of packaging materials will come sooner or later. The application of polylactic acid, which is harmless to the environment and beneficial to people's health, is an inevitable trend.

Advantage

1. Polylactic acid (PLA) is a new type of biodegradable material, which is made from starch raw materials proposed by renewable plant resources (such as corn). Starch raw material is saccharified to obtain glucose, and then fermented from glucose and certain strains to produce high-purity lactic acid, and then chemical synthesis method is used to synthesize polylactic acid with a certain molecular weight.

It has good biodegradability, and can be completely degraded by microorganisms in nature after use, and finally generates carbon dioxide and water, which does not pollute the environment, which is very beneficial to protect the environment and is recognized as an environmentally friendly material.

The treatment method of ordinary plastics is still incineration and cremation, which causes a large amount of greenhouse gases to be discharged into the air, while polylactic acid plastics are buried in the soil to degrade, and the carbon dioxide produced directly enters the soil organic matter or is absorbed by plants, and will not be discharged into the air. Does not cause greenhouse effect.

2. Good mechanical and physical properties. Polylactic acid is suitable for various processing methods such as blow molding and thermoplastic. It is easy to process and widely used. It can be used to process various plastic products, packaged food, fast food lunch boxes, non-woven fabrics, industrial and civilian fabrics from industry to civilian use. It is further processed into agricultural fabrics, health care fabrics, rags, sanitary products, outdoor UV-proof fabrics, tent fabrics, floor mats, etc. The market prospect is very promising.

3. Good compatibility and degradability. Polylactic acid is also widely used in the field of medicine, such as the production of disposable infusion equipment, non-disassembly surgical sutures, etc., and low molecular polylactic acid as drug sustained-release packaging.

4. In addition to the basic characteristics of biodegradable plastics, polylactic acid (PLA) also has its own unique characteristics. Traditional biodegradable plastics are not as strong, transparent and resistant to climate change as ordinary plastics.

JIANGSU TUBO NEW MATERIAL CO.,LTD our factory which is a high technology and comprehensive company specializing in integrated design, research and development, manufacture, sales and service.Headquarter Located in Jiading District, Shanghai. We are a professional manufacture new materials like PLA ,PTFE, EVA, PVC ,Acrylic And Wood-Plastic Composites and other more than ten series of materials of the new material company.

Based on the "quality" and "service",TUBO Materials has been widely used by customers all over the world. between team, within the team, we are sincere, cooperative attitude and determination to build our destiny and career community. Whether it is in management or in products, it is the driving force to maintain the superiority of our team.

Our Team