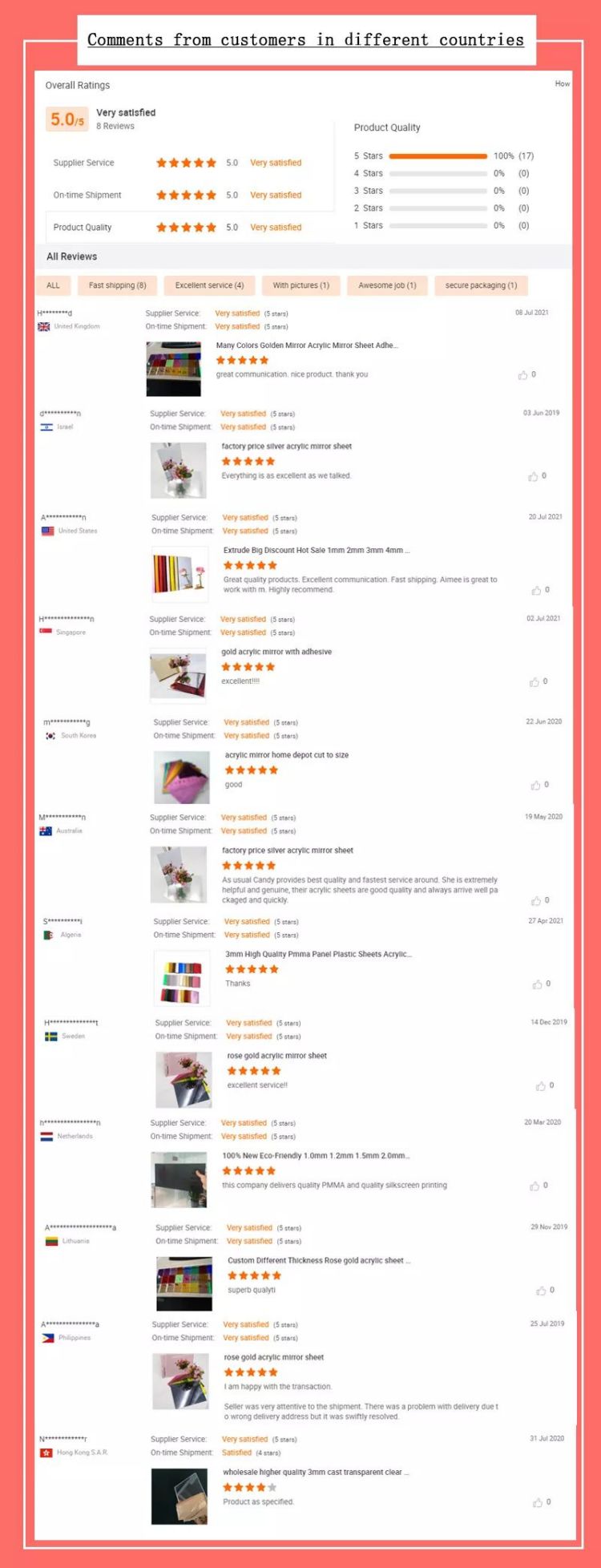

0.5mm 3mm 5mm Scratch Resistant Coating For Cast Extrude Clear Acrylic Sheet

Acrylic is an important plastic polymer material developed earlier, with good transparency, chemical stability and weather resistance, easy to dye, easy to process, beautiful appearance, widely used in the construction industry. Plexiglass products can usually be divided into cast plate, extruded plate and molded plastic.

Characteristic

1. With crystal-like transparency, the light transmittance is above 92%, the light is soft, the vision is clear, and the acrylic colored with dyes has a good color development effect.

2. Acrylic sheet has excellent weather resistance, high surface hardness and surface gloss, and good high temperature performance.

3. Acrylic sheet has good processing performance, which can be thermoformed or mechanically processed.

4. The transparent acrylic sheet has a light transmittance comparable to that of glass, but the density is only half of that of glass. In addition, it is not as brittle as glass, and even if broken, it will not form sharp shards like glass.

5. The wear resistance of acrylic sheet is close to that of aluminum, with good stability and corrosion resistance to various chemicals.

6. Acrylic sheets have good printability and sprayability. With proper printing and spraying processes, acrylic products can be given an ideal surface decoration effect.

7. Flame resistance: It is not self-igniting but is a flammable product and does not have self-extinguishing properties.

Types of acrylic sheets

There are many types of acrylic sheets.

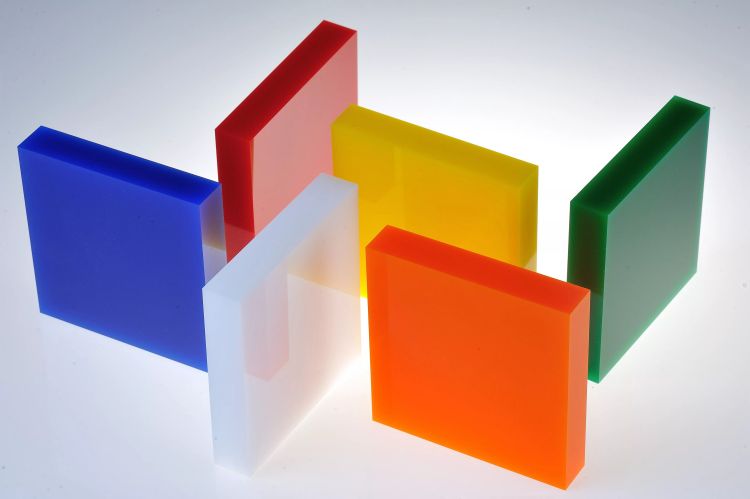

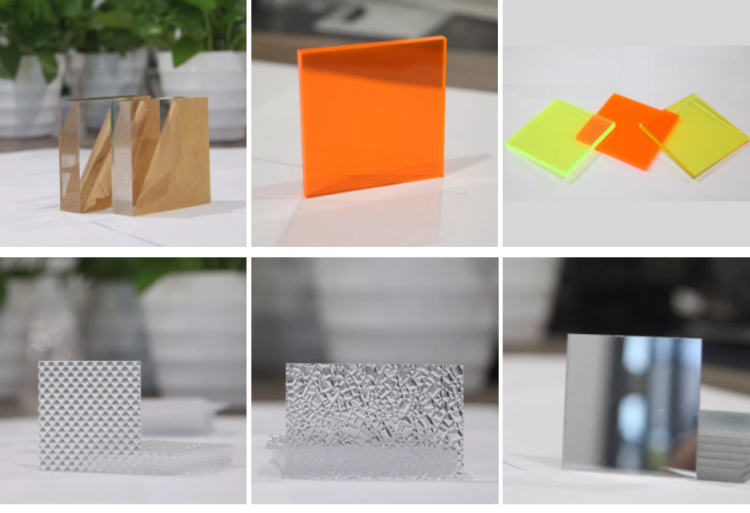

Common boards include: transparent board, dyed transparent board, milky white board, color board;

Special boards include: sanitary board, cloud board, mirror board, sandwich board, hollow board, impact board, flame retardant board, super wear-resistant board, surface pattern board, frosted board, pearl board, metal effect board, etc.

Different performance, different colors and visual effects to meet the ever-changing requirements.

Perspex sheet / PMMA sheet

Density | 1.2g/cm3 |

Color | clear, transparent, marble,frosted,mirror ,red,blue,white,black , more than 100 kinds of colors. No fading colour in outdoor at least 8-10 years. |

Material | adopt the pure LUCITE, high quality MMA raw material. |

Technology | cast acrylic sheet production process |

Equipment | Imported glass models (from Pilkington Glass in U. K. ) |

Quality | acrylic sheet conforms to the environmental protection standard, already through SGS environmental protection authentication. |

payment | L/C, T/T, Western Union, MoneyGram, Paypal |

MOQ | 50PCS |

Delivery | 6-9days after confirm your order |

Technical Properties

Specific Gravity | 1.19-1.20 |

Rockwell Hardness | M-100 |

Shear Strength | 630Kg/cm2 |

Tensile Strength | 760Kg/cm2 |

Yield Strength | 1260Kg/cm2 |

Rupture Strength | 1050Kg/cm2 |

Light Transmittance | 93% |

Refractive Index | 1.49 |

Heat Distortion Temperature | 100℃ |

Thermal Forming Temperature | 140℃-180℃ |

Coefficient of linear Thermal Expansion | 6×10-5cm/cm/℃ |

Dielectric Strength | 20Kv/mm |

Water(24HRS)Absorption | 0.30% |

Size

This is our factory normal size

Cast acrylic sheet | Net size/mm | Thickness range /mm:1.5-300 | |||

1000*2000 | 120*1800 | 1200*2440 | 1220*1830 | 1250*1850 | 1270*1870 |

1220*2440 | 1220*2450 | 1240*2460 | 1280*2500 | 1290*2510 | 1300*2500 |

1320*2540 | 1500*3000 | 1560*2580 | 1830*2440 | 2000*3000 | 2050*3050 |

2580*2660 |

|

|

|

|

|

| |||||

Frosted acrylic sheet | Net size/mm | Thickness range /mm:2.2-20 | |||

1200*2440 | 2000*3000 |

|

|

|

|

| |||||

Extrude acrylic sheet | Net size/mm | Thickness range /mm:0.8-20 | |||

1220*1830 | 1220*2440 | 2000*3000 | 2050*3050 |

|

|

| |||||

Mirror acrylic sheet | Net size/mm | Thickness range /mm:0.8-6 | |||

1000*2000 | 1220*1830 | 1220*2440 |

|

|

|

| |||||

Glitter/Marble acrylic sheet | Net size/mm | Thickness range /mm:2.5-30 | |||

580*1520 | 940*1540 | 960*1560 | 1200*1820 | 1220*2040 | 1220*2440 |

Note: we can make products size according customer requirmen