Anti Scratch Abrasion Resistance Shockproof Thin Clear Acrylic Sheet

Anti Scratch Abrasion Resistance Shockproof Thin Clear Acrylic Sheet

Description

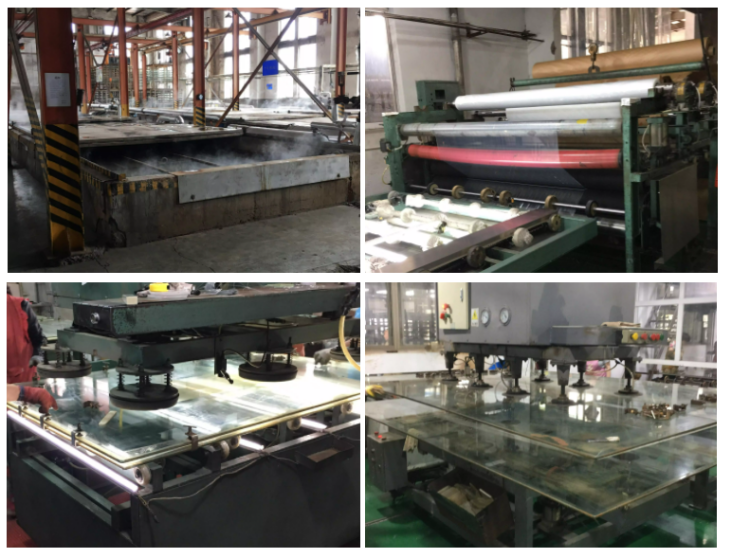

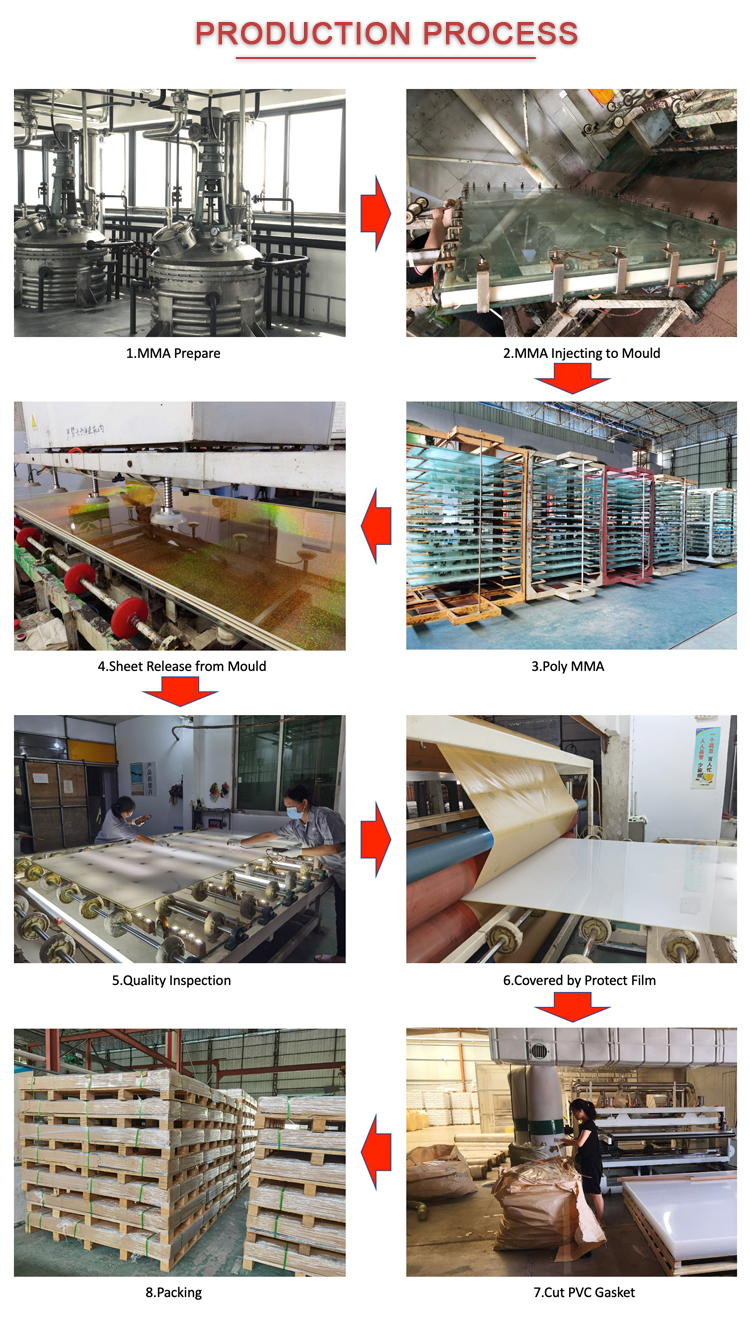

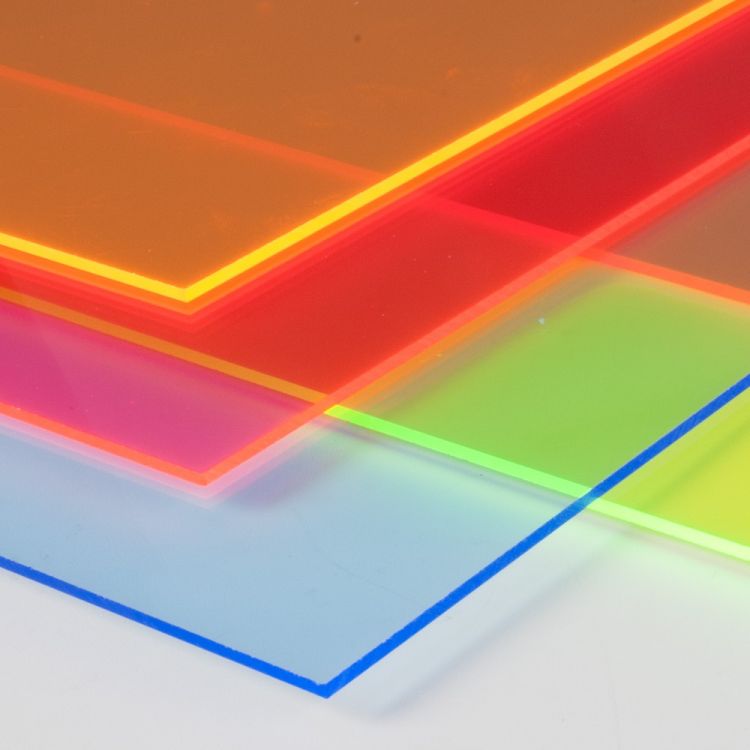

The chemical name of acrylic is polymethyl methacrylate. It is an important thermoplastic that was developed earlier. It has good transparency, chemical stability and weather resistance, easy to dye, easy to process, and beautiful appearance. It is widely used in the construction industry. Wide range of applications.

Acrylic sheet is a general term for acrylic and methacrylic chemicals. Includes monomers, sheets, pellets, resins, and composites.

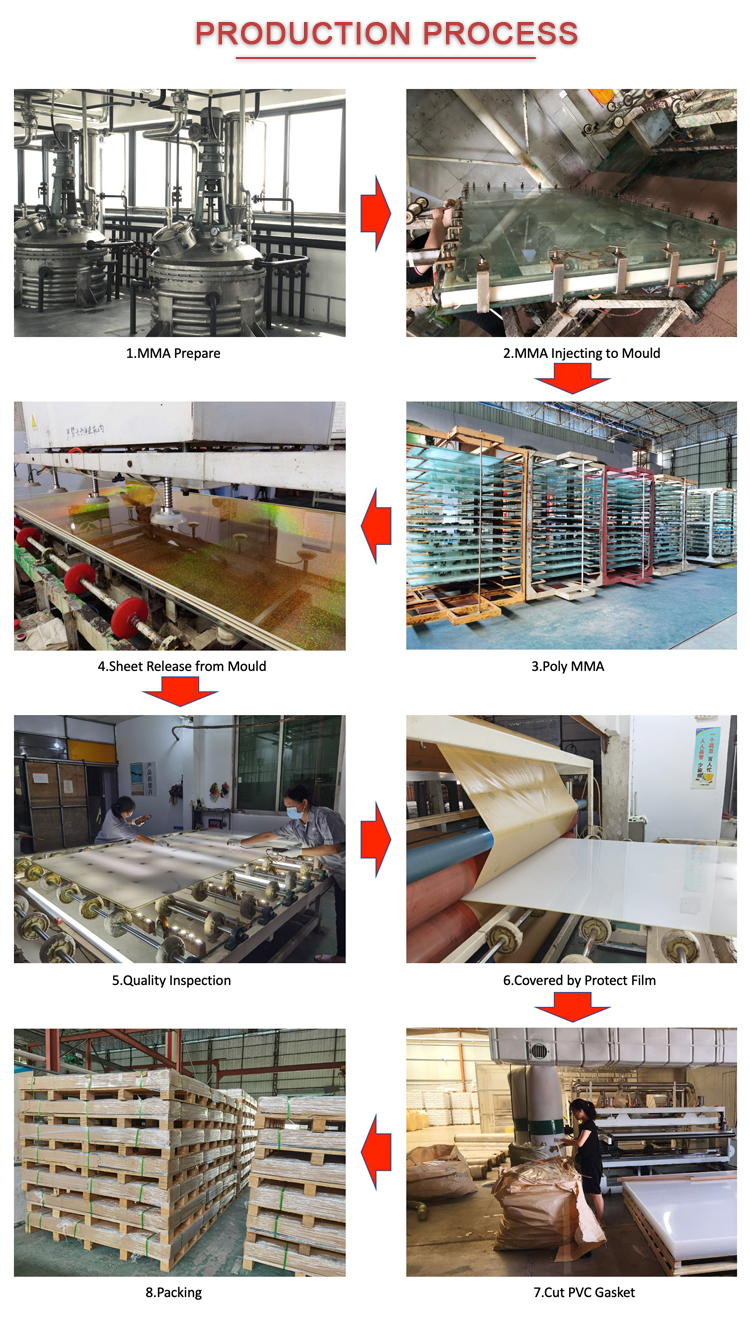

Acrylic sheet is polymerized from methyl methacrylate monomer (MMA), namely polymethyl methacrylate (PMMA) sheet plexiglass,

It is a kind of plexiglass processed by a special process. It has the reputation of "Plastic Queen".

The research and development of acrylic has a history of more than 100 years.

Acrylic sheets are divided into pure new materials, mixed materials and pure recycled materials from the raw materials.

Pure new material acrylic has excellent anti-ultraviolet performance, no yellowing, no fading, no cracking in 30 years, light transmittance is more than 93%; excellent anti-cracking and chemical resistance properties. The hand feels smooth and smooth, the surface gloss is high, and it is crystal clear.

Pure return material is made of recycled acrylic scraps, which are thermally degraded to obtain regenerated MMA (methyl methacrylate) monomer, and then obtained after chemical polymerization. After strict technological process, pure MMA monomer can be obtained again,

Mixed materials refer to the use of pure recycled materials and pure new materials to synthesize monomers, and there is no difference in quality. However, the produced degradable monomers are not of high purity, and their quality and performance are poor after the sheet is formed.

Characteristics of acrylic

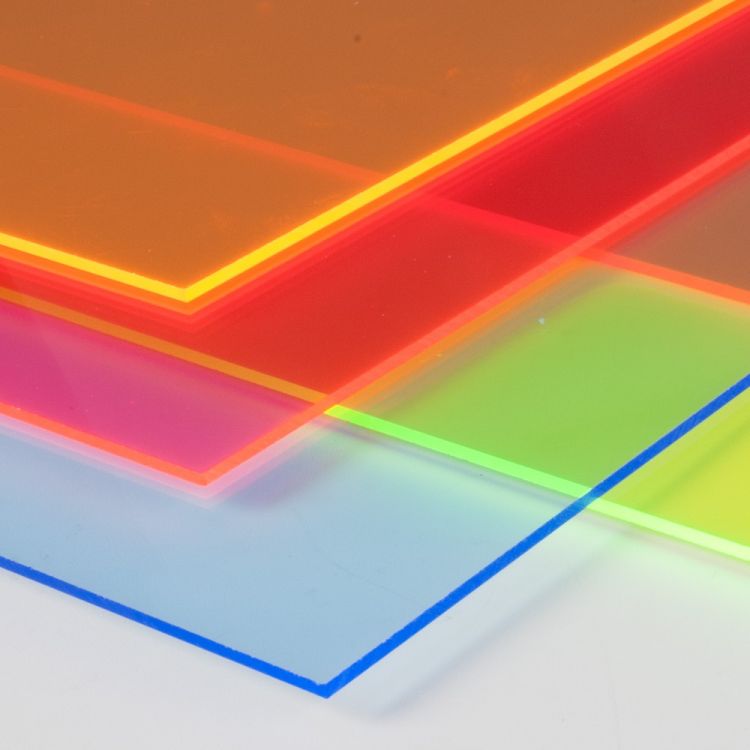

1. It has crystal-like transparency, the light transmittance is above 92%, the light is soft, the vision is clear, and the acrylic colored with dyes has a good color development effect.

2. Acrylic sheet has excellent weather resistance, high surface hardness and surface gloss, and good high temperature performance.

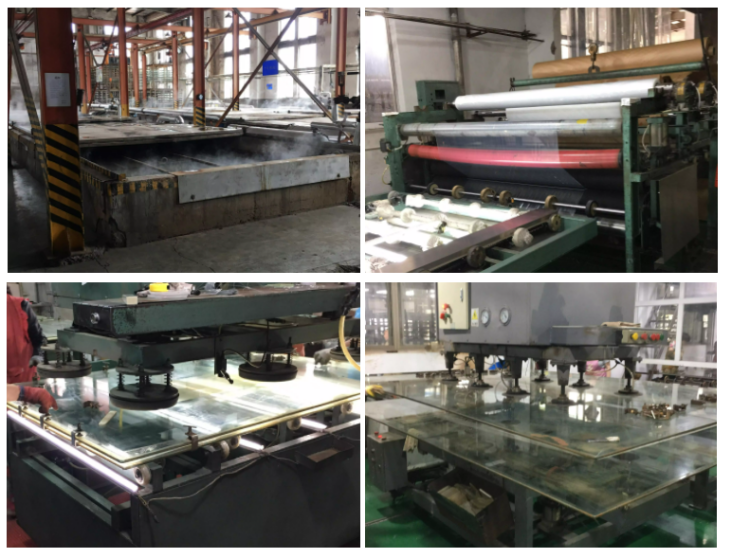

3. Acrylic sheet has good processing performance, which can be thermoformed or mechanically processed.

4. The transparent acrylic sheet has a light transmittance comparable to that of glass, but the density is only half of that of glass. In addition, it is not as brittle as glass, and even if broken, it will not form sharp shards like glass.

5. The wear resistance of acrylic plate is close to that of aluminum, with good stability and corrosion resistance to various chemicals.

6. Acrylic sheets have good printability and sprayability. With proper printing and spraying processes, acrylic products can be given an ideal surface decoration effect.

7. Flame resistance: It is not spontaneously combustible but belongs to flammable products and does not have self-extinguishing properties.

The main purpose

PMMA has the advantages of light weight, low price and easy molding. Its molding methods include casting, injection molding, machining, thermoforming, etc. In particular, injection molding can be mass-produced, with simple process and low cost. Therefore, its application is becoming more and more extensive, and it is widely used in instrumentation parts, automobile lights, optical lenses, transparent pipes, etc.

Acrylic sheet is a general term for acrylic and methacrylic chemicals. Includes monomers, sheets, pellets, resins, and composites.

Acrylic sheet is polymerized from methyl methacrylate monomer (MMA), namely polymethyl methacrylate (PMMA) sheet plexiglass,

It is a kind of plexiglass processed by a special process. It has the reputation of "Plastic Queen".

The research and development of acrylic has a history of more than 100 years.

Acrylic sheets are divided into pure new materials, mixed materials and pure recycled materials from the raw materials.

Pure new material acrylic has excellent anti-ultraviolet performance, no yellowing, no fading, no cracking in 30 years, light transmittance is more than 93%; excellent anti-cracking and chemical resistance properties. The hand feels smooth and smooth, the surface gloss is high, and it is crystal clear.

Pure return material is made of recycled acrylic scraps, which are thermally degraded to obtain regenerated MMA (methyl methacrylate) monomer, and then obtained after chemical polymerization. After strict technological process, pure MMA monomer can be obtained again,

Mixed materials refer to the use of pure recycled materials and pure new materials to synthesize monomers, and there is no difference in quality. However, the produced degradable monomers are not of high purity, and their quality and performance are poor after the sheet is formed.

2. Acrylic sheet has excellent weather resistance, high surface hardness and surface gloss, and good high temperature performance.

3. Acrylic sheet has good processing performance, which can be thermoformed or mechanically processed.

4. The transparent acrylic sheet has a light transmittance comparable to that of glass, but the density is only half of that of glass. In addition, it is not as brittle as glass, and even if broken, it will not form sharp shards like glass.

5. The wear resistance of acrylic plate is close to that of aluminum, with good stability and corrosion resistance to various chemicals.

6. Acrylic sheets have good printability and sprayability. With proper printing and spraying processes, acrylic products can be given an ideal surface decoration effect.

7. Flame resistance: It is not spontaneously combustible but belongs to flammable products and does not have self-extinguishing properties.