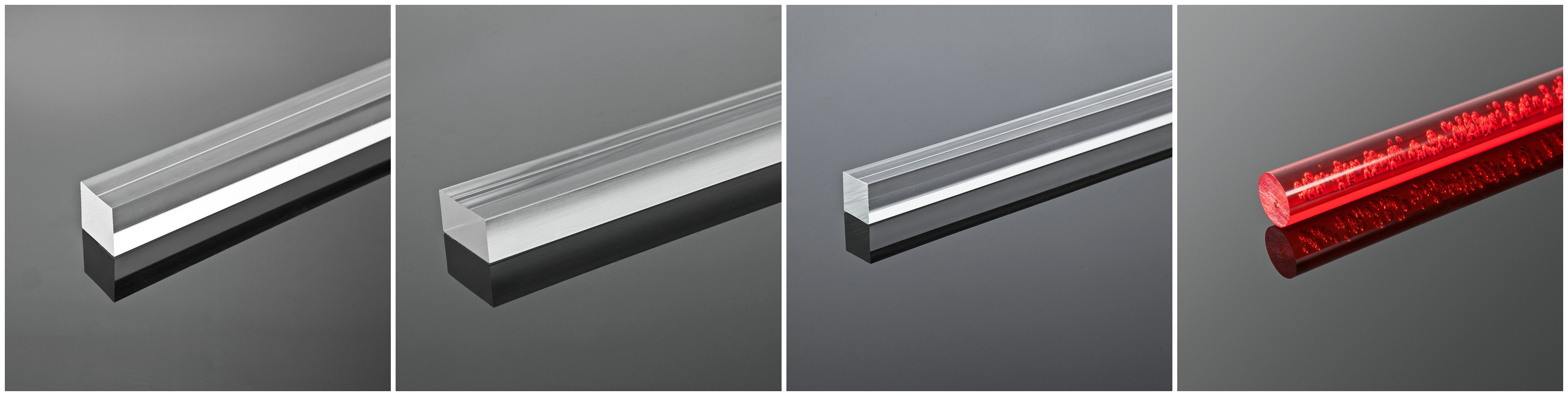

Acrylic Hot Selling Colorful Acrylic Welding Solid PMMA Rods

Destription Acrylic, also known as PMMA or plexiglass, derived from English acrylic (acrylic plastic), chemical name is polymethyl methacrylate. It is an important plastic polymer material developed earlier, with good transparency, chemical stability and weather resistance, easy to dye, easy to process, beautiful appearance, widely used in the construction industry. Plexiglass products can usually be divided into cast plate, extruded plate and molded plastic. Application of Acrylic Rod 1.Construction: show window, doors, light-absorpting shade, telephone booth. 2.Advertisement: lamphouse,signboard,indicator,display rack. 3.vehicle: door and window of car and train. 4.Medical: infant incubator, many kinds of medical apparatus. 5.Civilian goods: bath room, art work, cosmetics, bracket. 6.Industrial: instruments and meters and protecting cover 7.Lighting: daylight lamp, ceiling lamp,lamp shade OUR ADVANTAGES ♦ Product sructure design capability PE package,carton box ♦ CAD / CAM ♦ Provide sample ♦ Independent mould design capability ♦ Commissioning production capacity ♦ Rich stocks ♦ Materials development ♦ Quality Control by 24 hours PRODUCTION PROCESSING ♦ Using an extruding machine can make a fuller integration of plasticized materials. ♦ According to ISO Quality Control System to record the technology processing, all of product information can be traced. We strictly enforce the process, to ensure the product's consistency. ♦ Technology Department will analysis the feedback and constantly improve the technical maturity and quality stability. QUALITY CONTROL ♦ The product should pass five full- parametric test and a fully parametric sampling which from production to delivery, thus ensure product quality standards conforms with company's standards. ♦ Customer's special requirements will be joined and strictly enforced in the inspection standards, to ensure that customers are satisfied with our products. MATERIAL HEAT TREATMENT ♦ Annealing treatment of multiple materials can maximize removed the material's stress. In the latter of processing applications, materials can be more stable and durable. ♦ Each product has passed the STRESS TEST to ensure its stress in qualified ranges, reducing the risk of cracking and discard which caused by stress in the processing. JIANGSU TUBO NEW MATERIAL CO.,LTD our factory which is a high technology and comprehensive company specializing in integrated design, research and development, manufacture, sales and service.Headquarter Located in Jiading District, Shanghai. We are a professional manufacture new materials like PLA ,PTFE, EVA, PVC ,Acrylic And Wood-Plastic Composites and other more than ten series of materials of the new material company. Based on the "quality" and "service",TUBO Materials has been widely used by customers all over the world. between team, within the team, we are sincere, cooperative attitude and determination to build our destiny and career community. Whether it is in management or in products, it is the driving force to maintain the superiority of our team. FACTORY TOUR Packing and Shipping of Acrylic Rod Packing details: 1. One piece of acrylic rod or tube packing: covered with PE film, the covered film without any company sign. 2. Cartons and wooden frame/case will be packed in container. Shipping details: 1. By ocean shipping: 10-25days 2. By air transportation: 4-7days 3. By International express, like DHL, TNT, UPS, FEDEX, 3-5days(door to door)

.

.