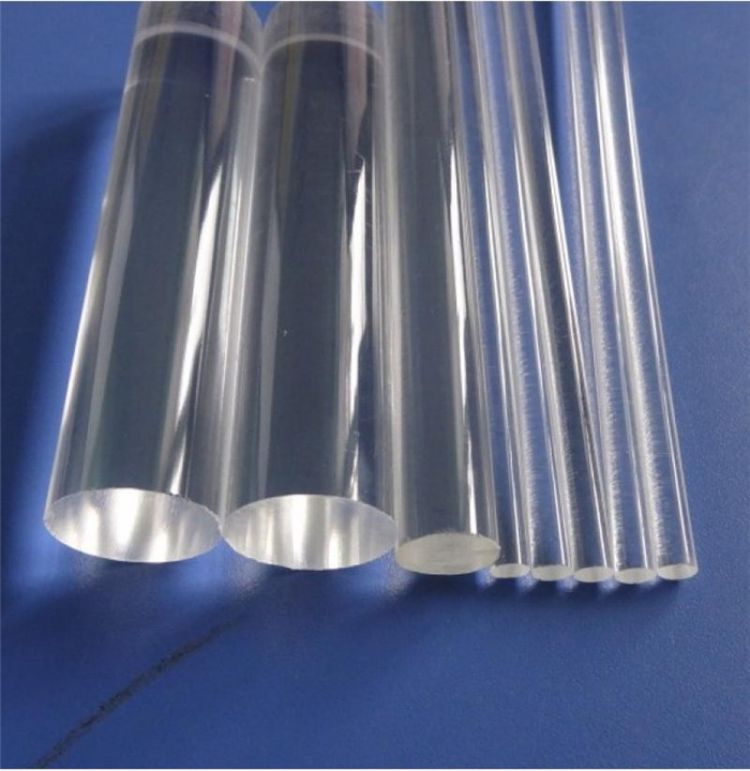

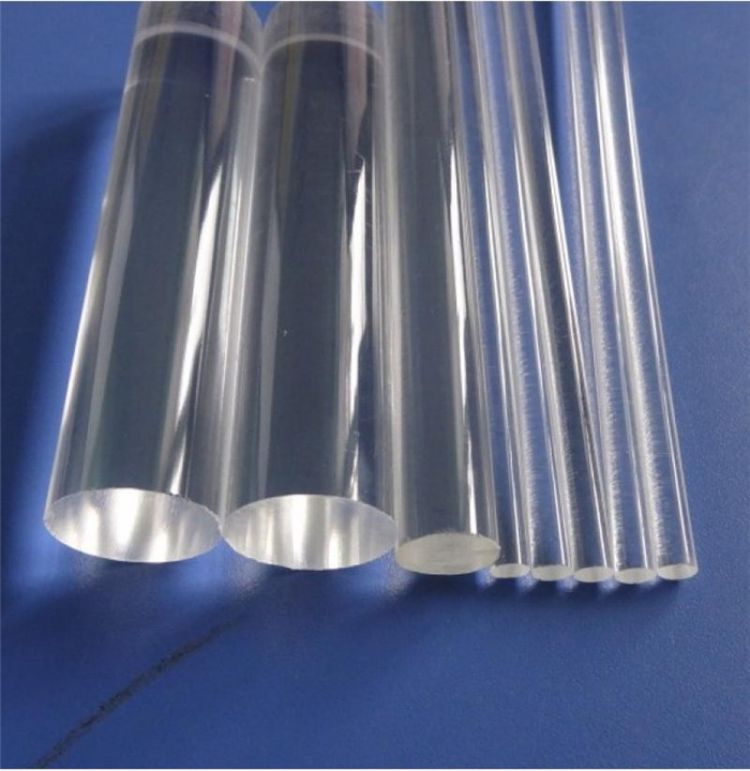

Acrylic Round Rod Transparent Clear Standard PMMA Rod

Acrylic Round Rod Transparent Clear Standard PMMA Rod

Acrylic is an important plastic polymer material developed earlier. It has good transparency, chemical stability and weather resistance, easy dyeing, easy processing, and beautiful appearance. It is widely used in the construction industry. Plexiglass products can generally be divided into cast sheets, extruded sheets and molding compounds.

Use

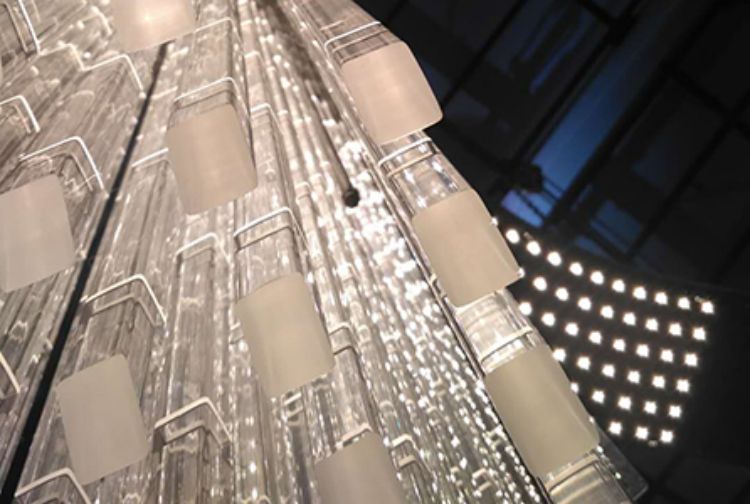

Acrylic products include acrylic sheets, acrylic plastic pellets, acrylic light boxes, signboards, acrylic bathtubs, acrylic artificial marble, acrylic resins, acrylic (latex) paints, acrylic adhesives, etc. There are a wide variety of products.

Acrylic products commonly seen by people are acrylic products assembled from raw materials such as acrylic pellets, sheets or resins through various processing methods and with various materials and functional parts. As for the commonly heard acrylic fiber, acrylic cotton, acrylic yarn, acrylic nylon, etc., it refers to the man-made fiber polymerized from acrylic acid and has nothing to do with acrylic products.

Among them, the acrylic sheet that people often say is the polymethyl methacrylate Polymeric Methyl Methacrylate (PMMA) sheet, which is polymerized from "methyl methacrylate monomer Methyl Methacrylate (MMA)". Or extruded from acrylic pellets through an extruder. In the past, the plate was commonly known as plexiglass. Acrylic comes from English acrylic, which means PMMA board made of organic compound MMA, its transparency and light transmittance are like glass. All sheets made from transparent plastics such as PS, PC, etc. or from inferior recycled MMA are collectively referred to as plexiglass. In order to distinguish, the PMMA board made of high-quality pure material MMA is named acrylic board to distinguish it from the general plexiglass board.

Characteristic

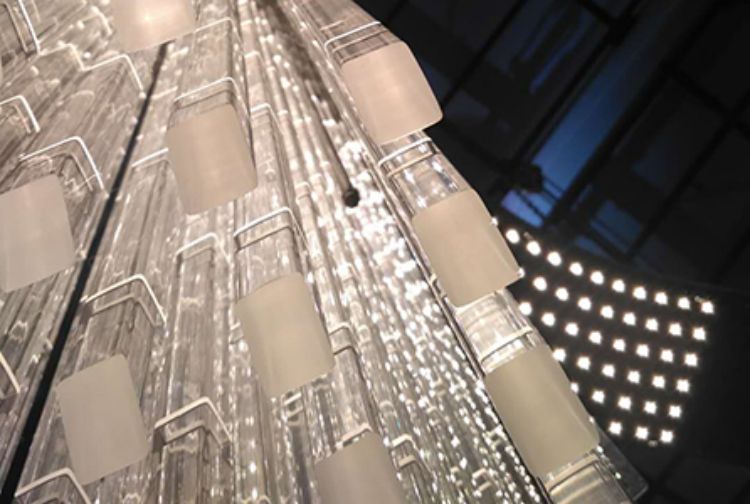

1. With crystal-like transparency, the light transmittance is above 92%, the light is soft, the vision is clear, and the acrylic colored with dyes has a good color development effect.

2. Acrylic sheet has excellent weather resistance, high surface hardness and surface gloss, and good high temperature performance.

3. Acrylic sheet has good processing performance, which can be thermoformed or mechanically processed.

4. The transparent acrylic sheet has a light transmittance comparable to that of glass, but the density is only half of that of glass. In addition, it is not as brittle as glass, and even if broken, it will not form sharp shards like glass.

5. The wear resistance of acrylic sheet is close to that of aluminum, with good stability and corrosion resistance to various chemicals.

6. Acrylic sheets have good printability and sprayability. With proper printing and spraying processes, acrylic products can be given an ideal surface decoration effect.

7. Flame resistance: It is not self-igniting but is a flammable product and does not have self-extinguishing properties.

There are many types of acrylic sheets.

Common boards include: transparent board, dyed transparent board, milky white board, color board;

Special boards include: sanitary board, cloud board, mirror board, plywood board, hollow board, impact board, flame retardant board, super wear-resistant board, surface pattern board, frosted board, pearl board, metal effect board, etc.

Different performance, different colors and visual effects to meet the ever-changing requirements.

Acrylic is an important plastic polymer material developed earlier. It has good transparency, chemical stability and weather resistance, easy dyeing, easy processing, and beautiful appearance. It is widely used in the construction industry. Plexiglass products can generally be divided into cast sheets, extruded sheets and molding compounds.

Use

Acrylic products include acrylic sheets, acrylic plastic pellets, acrylic light boxes, signboards, acrylic bathtubs, acrylic artificial marble, acrylic resins, acrylic (latex) paints, acrylic adhesives, etc. There are a wide variety of products.

Acrylic products commonly seen by people are acrylic products assembled from raw materials such as acrylic pellets, sheets or resins through various processing methods and with various materials and functional parts. As for the commonly heard acrylic fiber, acrylic cotton, acrylic yarn, acrylic nylon, etc., it refers to the man-made fiber polymerized from acrylic acid and has nothing to do with acrylic products.

Among them, the acrylic sheet that people often say is the polymethyl methacrylate Polymeric Methyl Methacrylate (PMMA) sheet, which is polymerized from "methyl methacrylate monomer Methyl Methacrylate (MMA)". Or extruded from acrylic pellets through an extruder. In the past, the plate was commonly known as plexiglass. Acrylic comes from English acrylic, which means PMMA board made of organic compound MMA, its transparency and light transmittance are like glass. All sheets made from transparent plastics such as PS, PC, etc. or from inferior recycled MMA are collectively referred to as plexiglass. In order to distinguish, the PMMA board made of high-quality pure material MMA is named acrylic board to distinguish it from the general plexiglass board.

Characteristic

1. With crystal-like transparency, the light transmittance is above 92%, the light is soft, the vision is clear, and the acrylic colored with dyes has a good color development effect.

2. Acrylic sheet has excellent weather resistance, high surface hardness and surface gloss, and good high temperature performance.

3. Acrylic sheet has good processing performance, which can be thermoformed or mechanically processed.

4. The transparent acrylic sheet has a light transmittance comparable to that of glass, but the density is only half of that of glass. In addition, it is not as brittle as glass, and even if broken, it will not form sharp shards like glass.

5. The wear resistance of acrylic sheet is close to that of aluminum, with good stability and corrosion resistance to various chemicals.

6. Acrylic sheets have good printability and sprayability. With proper printing and spraying processes, acrylic products can be given an ideal surface decoration effect.

7. Flame resistance: It is not self-igniting but is a flammable product and does not have self-extinguishing properties.

There are many types of acrylic sheets.

Common boards include: transparent board, dyed transparent board, milky white board, color board;

Special boards include: sanitary board, cloud board, mirror board, plywood board, hollow board, impact board, flame retardant board, super wear-resistant board, surface pattern board, frosted board, pearl board, metal effect board, etc.

Different performance, different colors and visual effects to meet the ever-changing requirements.

JIANGSU TUBO NEW MATERIAL CO.,LTD our factory which is a high technology and comprehensive company specializing in integrated design, research and development, manufacture, sales and service.Headquarter Located in Jiading District, Shanghai. We are a professional manufacture new materials like PLA ,PTFE, EVA, PVC ,Acrylic And Wood-Plastic Composites and other more than ten series of materials of the new material company.