Custom Acrylic Transparent Bubble Rod PMMA

PMMA is a polymer obtained by the polymerization of acrylic acid and its esters, collectively referred to as acrylic resins, and the corresponding plastics are collectively referred to as polyacrylic plastics, among which poly(methyl methacrylate) is widely used. The abbreviation code of polymethyl methacrylate is PMMA, commonly known as plexiglass, which is the best synthetic transparent material so far.

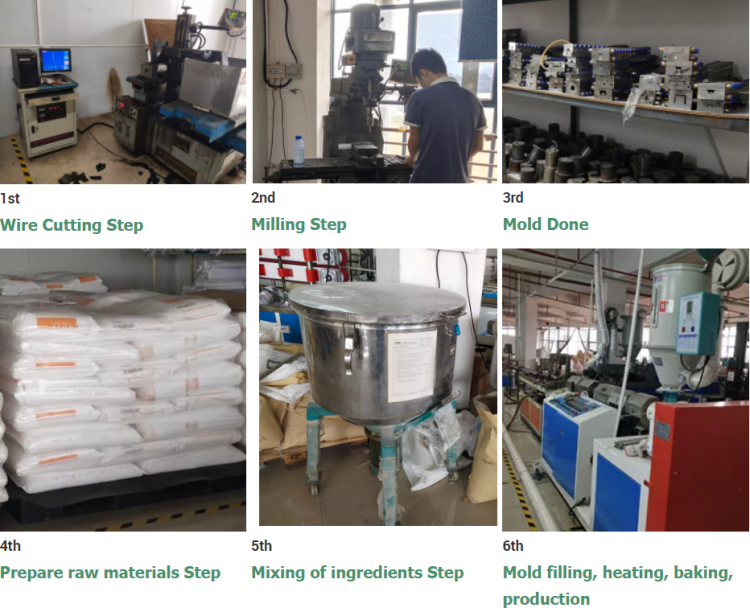

PMMA has the advantages of light weight, low price and easy molding. Its molding methods include casting, injection molding, machining, thermoforming, etc. In particular, injection molding can be mass-produced, with simple process and low cost. Therefore, its application is becoming more and more extensive, and it is widely used in instrumentation parts, automobile lights, optical lenses, transparent pipes, etc.

Application areas:

1. Architectural applications: shop windows, soundproof doors and windows, lighting covers, telephone booths, etc.

2. Advertising applications: light boxes, signs, signs, display stands, etc.

3. Transportation applications: doors and windows of vehicles such as trains, cars, etc.

4. Medical applications: baby incubators, various surgical medical appliances, civilian products: sanitary facilities, handicrafts, cosmetics, brackets, aquariums, etc.

5. Industrial application: instrument panel and cover, etc.

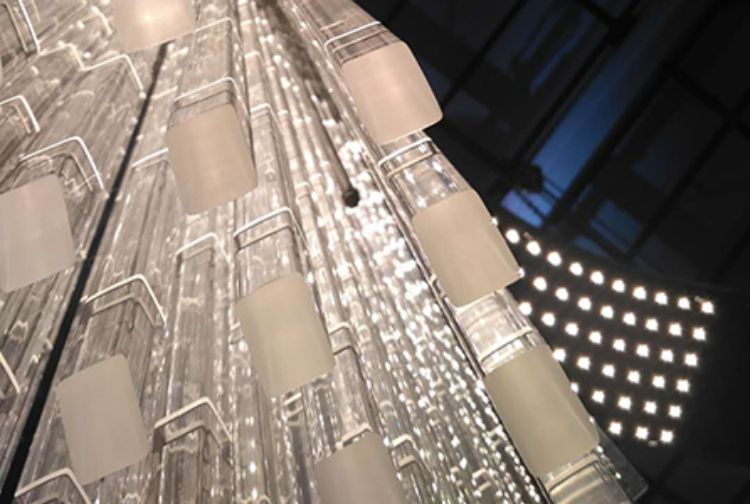

6. Lighting applications: fluorescent lamps, chandeliers, street lampshades, etc.

Application areas: hotels, shopping malls, office buildings, clubs, villas, museums, medical care, education, catering, exhibitions, etc.

Application areas: ceilings, integrated ceilings, partitions, screens, sliding doors, transparent walls, hotel furniture, office furniture, bar counters, lighting, chandeliers, signs, signs, floors, landscapes, etc.

Advantage

Acrylic is a good new material for making sanitary ware after ceramics. Compared with traditional ceramic materials, in addition to its unparalleled high brightness, acrylic has the following advantages: good toughness, not easy to be damaged; strong repairability, as long as you use soft foam to dip a bit of toothpaste to wipe the sanitary ware; soft texture, winter There is no cold and biting feeling; the colors are bright, which can meet the individual pursuit of different tastes. Using acrylic to make basins, bathtubs and toilets is not only beautiful in style, durable, but also environmentally friendly. Its radiation is almost the same as that of the human body's own bones. Acrylic sanitary ware first appeared in the United States and has occupied more than 70% of the entire international market.

Acrylic products include acrylic sheets, acrylic plastic pellets, acrylic light boxes, signboards, acrylic bathtubs, acrylic artificial marble, acrylic resins, acrylic (latex) paints and other products. Acrylic products commonly seen by people are acrylic products assembled from raw materials such as acrylic pellets, sheets or resins through various processing methods and with various materials and functional parts. As for the commonly heard acrylic fiber, acrylic cotton, acrylic yarn, acrylic nylon, etc., it refers to the man-made fiber polymerized from acrylic acid and has nothing to do with acrylic products.

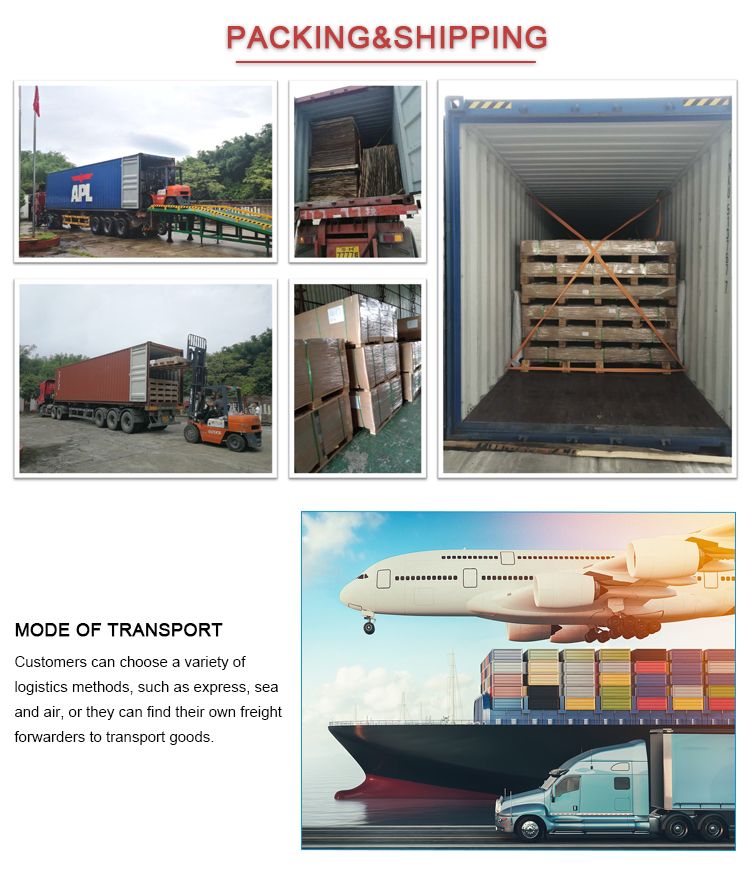

JIANGSU TUBO NEW MATERIAL CO.,LTD our factory which is a high technology and comprehensive company specializing in integrated design, research and development, manufacture, sales and service.Headquarter Located in Jiading District, Shanghai. We are a professional manufacture new materials like PLA ,PTFE, EVA, PVC ,Acrylic And Wood-Plastic Composites and other more than ten series of materials of the new material company.

Based on the "quality" and "service",TUBO Materials has been widely used by customers all over the world. between team, within the team, we are sincere, cooperative attitude and determination to build our destiny and career community. Whether it is in management or in products, it is the driving force to maintain the superiority of our team.